Aseptic Isolator for QC Labs and Pharmaceutical Producers Machine

HBWG sterile isolator is a device or system equipped with Class A ventilation, and can always completely isolate the internal environment from the external environment (such as the clean room or operator in which it is located).

It is used for the aseptic production and testing of sterile / highly toxic (live) drugs and drugs with poor stability, including laboratory sterility testing and routine testing of final product quality control.

Suitable for pharmaceutical, food and fine chemical industries. Comply with GMP and FDA requirements.

Features:

1. VHP sterilization equipment can be integrated;

2. Laminar air supply is used inside the cavity, and the air manifold is strictly controlled to ensure the purification level;

3. Real-time monitoring and automatic control of pressure, temperature, humidity and wind speed inside the cavity;

4. Continuous delivery is possible, suitable for large-scale sterility testing;

5.Waste can be quickly transferred from the work area through RTP, αβ valve or continuous bag to ensure the internal environment of the isolator is clean (optional);

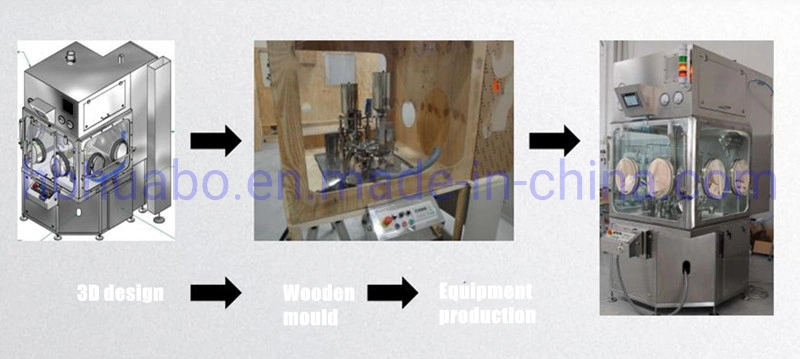

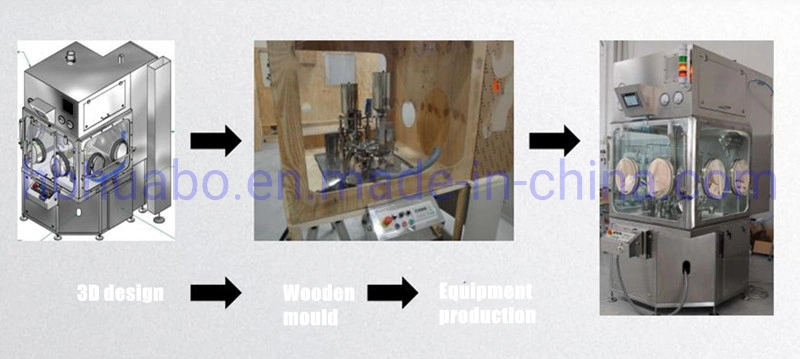

According to customer needs, customize various non-standard sizes;

Working Principle:

In a closed environment, the fan filter unit (high efficiency filter, HEPA) achieves the specified number of clean air changes, so that the internal environment of particles and microorganisms is continuously controlled.

And by adjusting the proportion of the exhaust valve, the pressure gradient of each section inside the isolator is realized.

The positive pressure mode mainly protects products and processes, and is used for aseptic operation of the inner cavity.

The negative pressure mode mainly protects the operator from external harmful substances, and protects the operator during the purification process, which is used for the highly toxic operation of the internal cavity.

HBWG sterile isolator is a device or system equipped with Class A ventilation, and can always completely isolate the internal environment from the external environment (such as the clean room or operator in which it is located).

It is used for the aseptic production and testing of sterile / highly toxic (live) drugs and drugs with poor stability, including laboratory sterility testing and routine testing of final product quality control.

Suitable for pharmaceutical, food and fine chemical industries. Comply with GMP and FDA requirements.

Features:

1. VHP sterilization equipment can be integrated;

2. Laminar air supply is used inside the cavity, and the air manifold is strictly controlled to ensure the purification level;

3. Real-time monitoring and automatic control of pressure, temperature, humidity and wind speed inside the cavity;

4. Continuous delivery is possible, suitable for large-scale sterility testing;

5.Waste can be quickly transferred from the work area through RTP, αβ valve or continuous bag to ensure the internal environment of the isolator is clean (optional);

According to customer needs, customize various non-standard sizes;

Working Principle:

In a closed environment, the fan filter unit (high efficiency filter, HEPA) achieves the specified number of clean air changes, so that the internal environment of particles and microorganisms is continuously controlled.

And by adjusting the proportion of the exhaust valve, the pressure gradient of each section inside the isolator is realized.

The positive pressure mode mainly protects products and processes, and is used for aseptic operation of the inner cavity.

The negative pressure mode mainly protects the operator from external harmful substances, and protects the operator during the purification process, which is used for the highly toxic operation of the internal cavity.