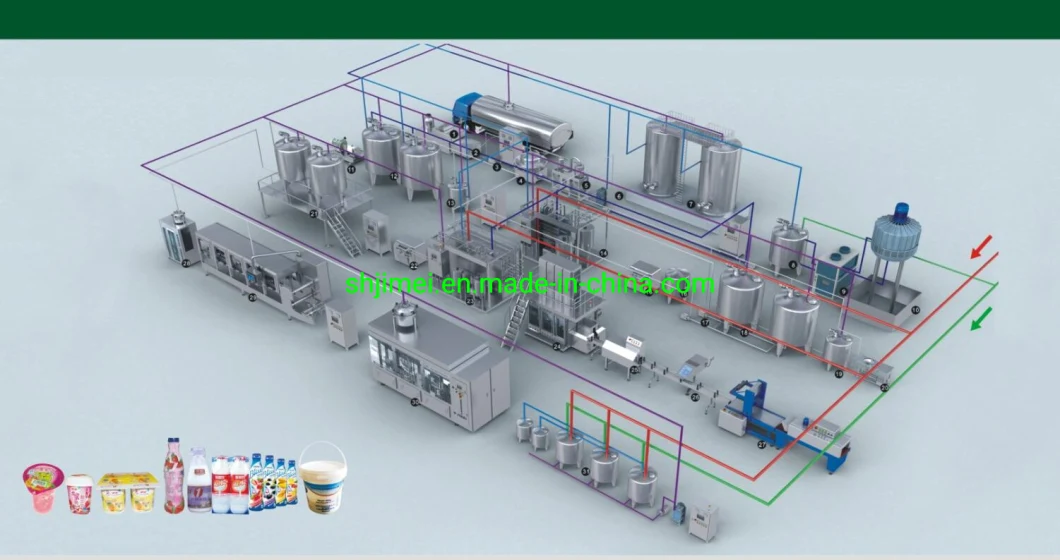

UHT milk production line pasteurized milk produciton line

We are looking for sole agent for each country world wild,please contact us.

What is long-life milk?

The name "long-life milk" is used to describe milk that's been treated in special ways to help it last longer outside a refrigerator or cooled environment.

Long life milk benefits are the same as any other type of milk, as it contains the same essential nutrients.

The difference between fresh and long-life milk is the method of processing. Fresh (pasteurised) milk is heated to 74°C for 15 seconds. Long-life milk is heated to 140°C for two seconds and then packaged aseptically.

The increased temperature at which long-life milk is treated results in a greater reduction in bacteria and heat-resistant enzymes in comparison to milk that undergoes regular pasteurisation - giving it an extended shelf life.

Long life milk can be stored for up to six months in a pantry, but once opened it needs to be refrigerated. Then it can be used normally like fresh milk within seven days.

You might also see long life milk referred to as "ultra heat treatment (UHT)" milk. Long life or UHT milk is available in forms like full-fat, reduced-fat, low-fat, modified and skim.

The name "long-life milk" is used to describe milk that's been treated in special ways to help it last longer outside a refrigerator or cooled environment.

Long life milk benefits are the same as any other type of milk, as it contains the same essential nutrients.

The difference between fresh and long-life milk is the method of processing. Fresh (pasteurised) milk is heated to 74°C for 15 seconds. Long-life milk is heated to 140°C for two seconds and then packaged aseptically.

The increased temperature at which long-life milk is treated results in a greater reduction in bacteria and heat-resistant enzymes in comparison to milk that undergoes regular pasteurisation - giving it an extended shelf life.

Long life milk can be stored for up to six months in a pantry, but once opened it needs to be refrigerated. Then it can be used normally like fresh milk within seven days.

You might also see long life milk referred to as "ultra heat treatment (UHT)" milk. Long life or UHT milk is available in forms like full-fat, reduced-fat, low-fat, modified and skim.

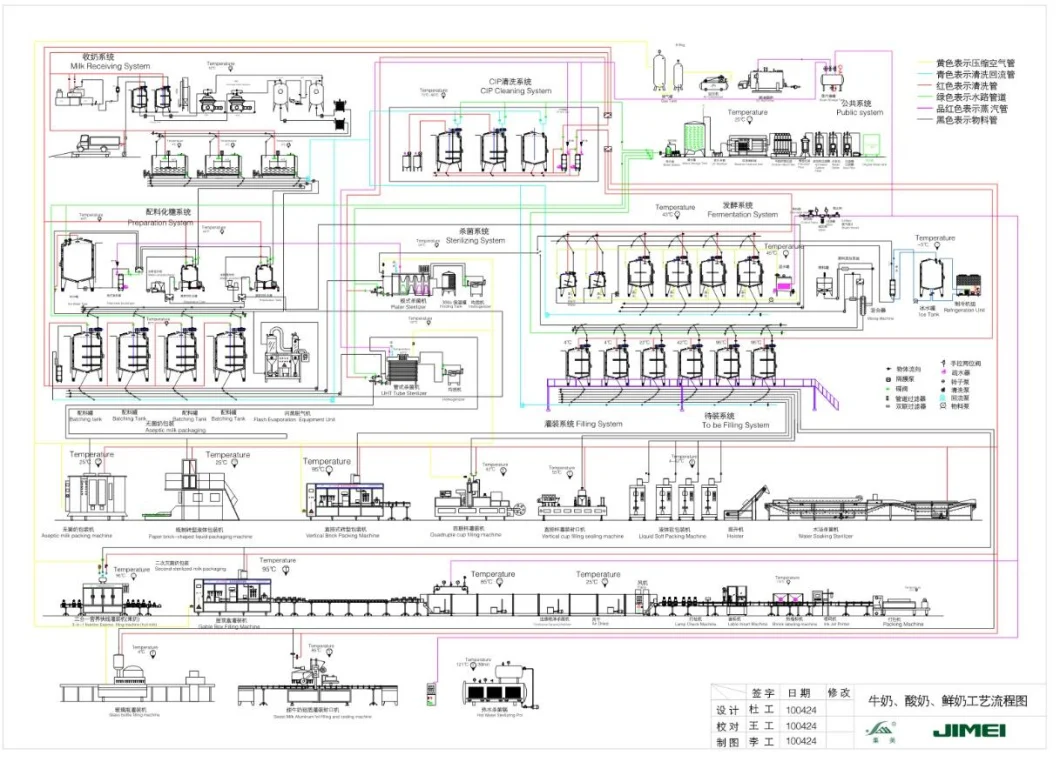

a milk processing 3 D flow chart

what is listed in the procedure

1. Water Treatment section:

Sand filter

Activated carbon filter

Water softener

Precision filter

Reverser osmosis filter

Electrical control system

UV filter

Water storage tank

2. Milk Receiving Section

Out door storage tank

Milk weight tank

Milk receiving tank

Temporary storage tank

Duplex filter

Milk Separator

Plate heat exchanger

Milk Storage Tank

3. Sugar Melting System

Hot water tank

Plate heat exchanger

Round high speed emulsification tank

Water-powder mixer

Mixing tank

4. Sterilization Section

Plate sterilizer

Warm keeping tank

High pressure homogenizer

Tube UHT sterilizer

Balance tank

5. Filling Packing Section

According the customer require.

6. CIP Cleaning Section

Acid tank

Alkali tank

Hot water tank

Pleat heat exchanger

Cleaning pump

7. Chiller Section

Chiller

Cooling tower

Chiller water tank

8. Compressor

Air compressor

Air filter

Air dryer

Air storage tank

9. Cooling Room

product package and delivery

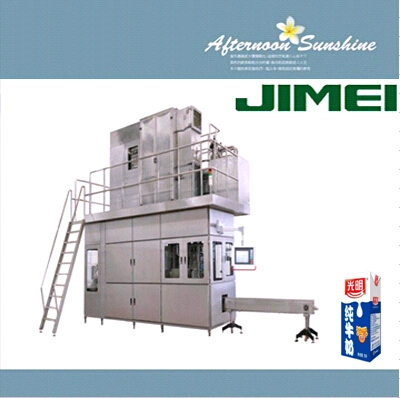

The most important machine, aseptic filling machine

Our certificate and patents

Our certificate and patents

our emplyees

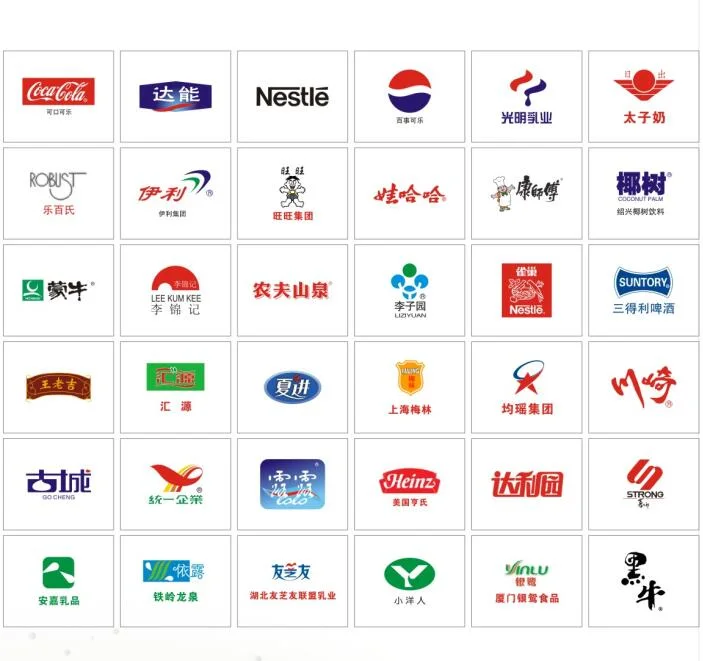

our customers

Packaging Details: be packed in nylon cloth and plastic film;

Delivery: machines will be shipped as soon as possible once we received the payments, normally Shipped in 90 days after payment.

our service

1.Allotted for equipment inspector certificate and manual , to ensure that users properlu installed and used.

2.Equipment to reach the destination ,the company will send engineers to guide installation and commissioning and customer training until satisfied.

3.The warranty period will be free to customers wearing accessories, shelf life outside of my company to pay parts at cost.

4.Our company provide lifelong maintenance service, including if necessary, to send engineers to the customer at the service.

FAQ

1.How long can I receive your reply after I send my inquiry?

We will reply you within 12 hours on workday.

2.Are you a manufacturer or a commercial company?

We are a manufacturer, and we have a foreign trade department, we market our own products.

3.What products can you provide?

We mainly produce beverage production machinery and equipment.

4.What are the application fields of your products?

Our products are mainly used by beverage factories or individuals who want to run a milk production plant.

5.Can you provide customized products?

Yes, all production line are customized. We can develop and manufacture products according to customer's drawing or sample. Saving customer's time on finding corollary equipment.

6.How's your production capacity?

deponds on customer requirement.

7.How many employees do you have?

We have over 100 employees,not including oversea technicians and engineers team.

8.How do you ensure your product quality?

We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

9.Payment?

We will confirm the payment with you when quoting, like FOB, CIF, CNF or others.

In batch production, we accept 30% deposit, balance against the copy of B/L.

T/T is the main payment, and L/C is acceptable as well.

10.What's your delivery method?10.What's your delivery method?

We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

11.Where do you mainly export your products?

Our products are mainly exported to Mexico, Saudi Arabia, India, Algeria, Dubai, Congo, African countries, etc.

Competitive AdvantagesWell and High Quality Control ,

Prompt Delivery ,

New Product ,

Customer's Design and Logo are Welcome ,

Competitive Prices ,

Earth-friendly Products ,

In a Variety of Design ,

Small Order Acceptable ,

ODM Accepted ,

OEM Accepted

Trade Information

1. Package- all equipments packed in nylon cloth and plastic film worthy of sea shipping.

2. Payment- 30% of total amount paid by T/T in advance and the balance paid by T/T after inspection and before shipment.

3. Delivery- in 60 days upon receipt of down payments.

4. Warranty-all machines & equipments are of one year warranty and life long maintenance offered by seller.

5. Installation- the seller arrange engineer to set up the equipments and train the operation workers for free, till qualified products are produced and maintenance in normal running, the buyer bear the round air tickets and local accommodation for the seller's engineer.