Chemical mixing tank liquid detergent mixer liquid mixer agitator

The material is stirred through the center of the upper part of the emulsifying pan, and the PTFE scraper plate always caters to the shape of the mixing pot, sweeps away the wall-sticking material, and causes the scraped material to produce a new interface continuously, and then cuts off, compresses and folds the blade and the rotating blade. Make it agitate, mix and flow down to the homogenizer below the pot, and the material is cut through the process of strong cutting, impact and turbulence between the high-speed rotating cutting wheel and the fixed cutting sleeve, and the material is cut in the shear seam. The particles of 200nm-2um were broken rapidly. Because of the vacuum in the emulsifying tank, the bubbles produced in the stirring process of the material were extracted in time. By means of vacuum extraction, the products produced are no longer mixed with bubbles in the stirring process, thus ensuring the production of high-quality products full of luster, fineness and good extensibility.

Specification:

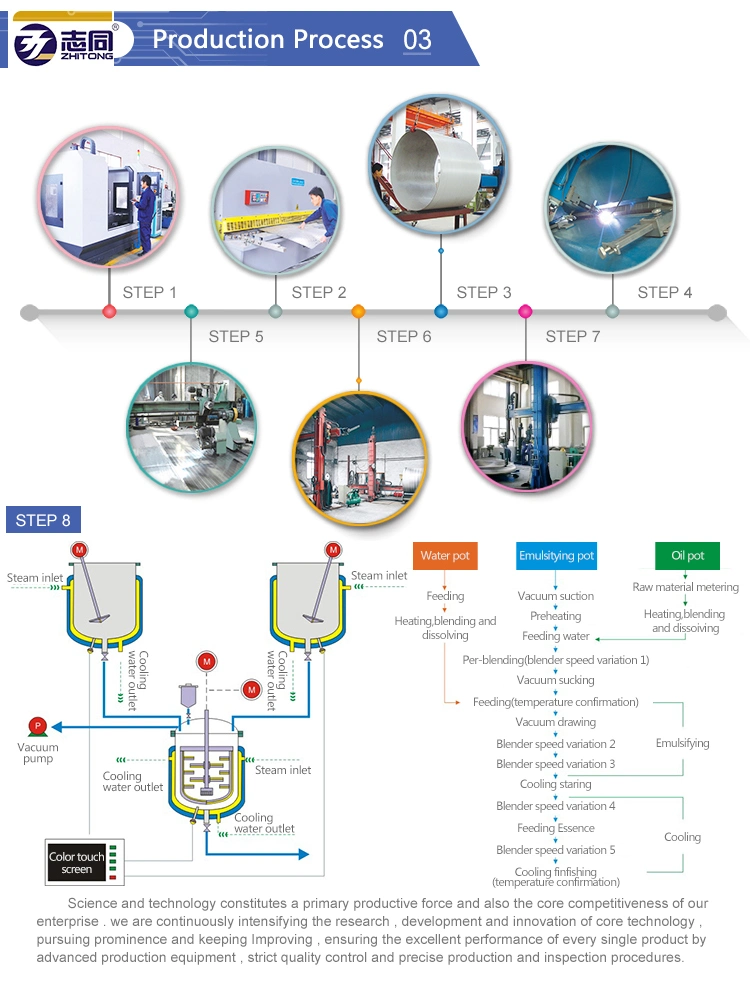

1)This mixer is three layers and including cooling, heating and heating insulation. Like the picture as following. And this one is the high quality and hot sale at domestic and abroad.

2) It is mainly suitable for preparation of foodstuff,.pharmacy and liquid detergents (such as liquid soap,cleanser essence, shampoo and shower cream,detergent etc.).

3)Integrating blending, homogenizing dispersing, heating and cooling etc functions, the reacting machine is an ideal device for liquid preparation in various factories.

4)This machine is three layers. The jacket is use for heating and cooling. And including stair and platform

| Model | Capacity (liter) | Mixing Power (KW) | Mixing Speed (r/min) | Homogenizer Power (KW) | Homogenizer Speed (r/min) | Heating Method |

| ZT-100L | 100 | 0.75 | 0~63 | 1.5 | 0~3000 | steam heating or electric heating optional |

| ZT-200L | 200 | 1.5 | 0~63 | 2.2 | 0~3000 | |

| ZT-500L | 500 | 2.2 | 0~63 | 4 | 0~3000 | |

| ZT-1000L | 1000 | 4 | 0~63 | 5.5 | 0~3000 | |

| ZT-2000L | 2000 | 5.5 | 0~63 | 7.5 | 0~3000 | |

| ZT-3000L | 3000 | 7.5 | 0~63 | 11 | 0~3000 | |

| ZT-5000L | 5000 | 11 | 0~63 | 18.5 | 0~3000 |

Product description:

This Liquid Mixing Machine is mainly applied for manufacturing liquid washing products, such as shampoo, detergent, liquid soap, shower gel. Also can produce other liquid products, such as wax, hair removal, paint, etc. It's composed of main pot, auxiliary boiler, stainless steel feeding pump, bracket platform, control system.

Hand sanitizer making machine, liquid detergent mixer, liquid soap making machine has high speed disperser . mixing and disperse viscously, solid and liquid etc.

Various kind of raw material will be dissolve which is such as AES, AESA LSA, during liquid production which can save energy consumption and shorten production the and shorten production period.

Main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed to produce liquid washing products, like shampoo, liquid soap, bath shower, dish washing, hand washing, lubricating oil, etc.

Finished products of Hand sanitizer making machine, liquid detergent mixer, liquid soap making machinecan be discharged by valve or match a screw pump.

High speed disperser.

1. Might mixing and disperse viscously, solid and liquid detergent etc.

2. Various kind of raw material will be dissolve which is such as AES, AESA LSA.

3. During liquid production, it can save energy consumption and shorten production period.

v Main adopts stepless timing device. Reduce babble occur under low temperature and high viscosity condition less air bubble will be formed.

v To produce liquid washing products. - Such as shampoo, liquid soap, bath shower, dish washing, hand washing, lubricating oil, etc.

v Finished products can be discharged by valve or match a screw pump.

V. Good materials. - Adopting imported 316L stainless steel materials, inside and outside polishing, conforming to GMP standards.