Biomass Electricity Generation Equipment Gasification Power Generator

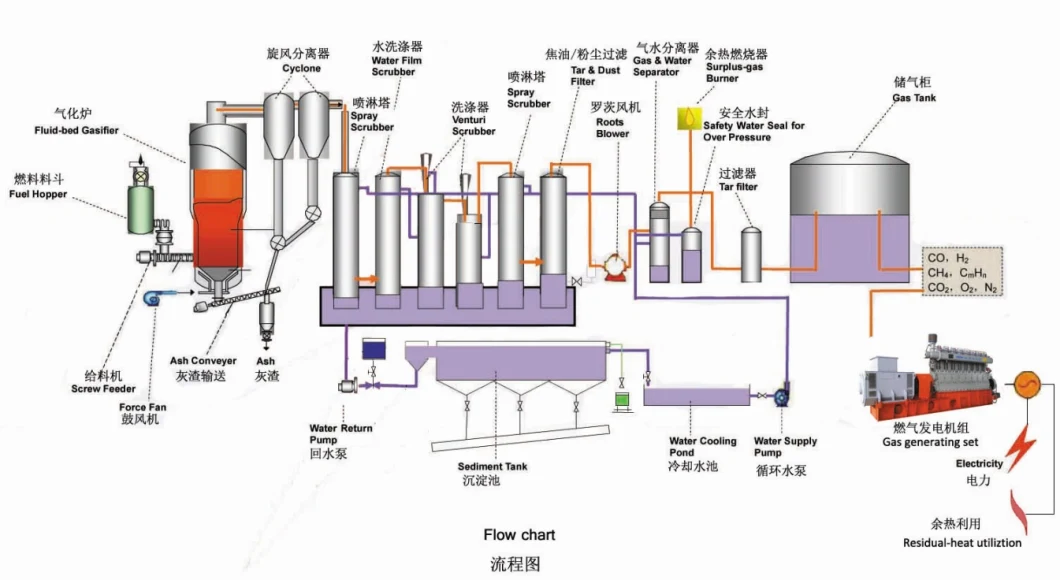

Forest waste and branch; agricultural straw, cotton stalks; rice husk; sugar cane residue in sugar mills; and sawdust in wood processing plants, these raw material through incomplete combustion in gasifier produce combustible gas which carbon monoxide is the main ingredient, after necessary purification can be used to generate electricity. While exhaust heat from the engine can be used to produce hot water or steam, to achieve a comprehensive and efficient use of biomass energy.

Typical biomass gas composition

From feedstocks wood chip

Component | CO | H2 | CH4 | CmHn | H2S | CO2 | O2 | N2 |

Percentage | 23.5% | 7.68% | 5.32% | 0.75% | --- | 10% | 0.11% | 52.4% |

Component | CO | H2 | CH4 | CmHn | H2S | CO2 | O2 | N2 |

Percentage | 17.2% | 4.05% | 6.82% | 1.24% | --- | 15.1% | 0.8% | 54.7% |

Biomass Gas Quality Suggested

- Gas temperature≤40ºC

- Gas pressure 2.5~10kPa

- Pressure change rate≤1kPa/min

- Calorific value ≥ 4.0MJ/Nm3

- Moisture content≤40g/Nm3, no free water

- Impurity content≤30mg/Nm3

- Impurity size≤5μm

- Tar content≤50mg/Nm3

- H2S≤50mg/Nm3

- Total sulfur≤100mg/Nm3

- NH3≤20mg/Nm3

- Cl≤50mg/Nm3

- H2≤50%

- O2≤1%

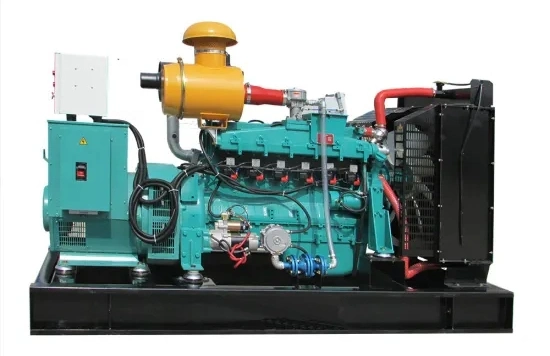

Biomass Gas Generator Specification

| Model Number (Engine Type) | (Styer,Jichai,Zichai) |

| Prime Power/Standby Power | 10kW-500kW/110kW-550kW |

| Rated Speed | 1500/1800RMP |

| Rated Frequency | 50/60Hz |

| Rated Voltage | 400V/230V |

| Phase | AC 3-Phase, 4 wire |

| Gas consumption | Biomass:2m3.kw/h |

| Starting System | DC 24V electric motor |

| Cooling method | Water-cooled |

| Alternator | Faraday,Siemens |

| Exciting method | brushless |

| Item | Technical specification | |||||

| Engine | Model | 6300D/M | 6300D/M-1 | 8300D/M-1 | 8300D/M-2 | 8300D/M-3 |

| Type | Inline, water cooled, four stroke, spark plug ignition | |||||

| Non-turbocharged | ||||||

| Cylinder number | 6 | 8 | ||||

| Cylinder diameter (mm) | 300 | |||||

| Rated speed(r/min) | 500 | 600 | 500 | 600 | 600 | |

| Rated power (kW) | 400 | 440 | 500 | 550 | 660 | |

| Rated thermal consumption(MJ/kW·h) | ≤11.0 | |||||

| Rotate direction (From flywheel) | Clockwise | |||||

| Start mode | Compressed air/motor start | |||||

| Exhaust temperature (ºC) | ≤600 | |||||

| Oil consumption(g/kW·h) | ≤0.8 | |||||

| Generator set | Type | 350GFM | 400GFM | 450GFM | 500GFM | 600GFM |

| Rated power(kW) | 350 | 400 | 450 | 500 | 600 | |

| Frequency(HZ) | 50 | |||||

| Voltage(V) | 400/6300/10500 | |||||

| Current(A) | 631/40/24 | 722/46/28 | 812/52/31 | 902/57/34 | 1083/69/41 | |

| Power factor (COSΦ) | 0.8 (Lagging) | |||||

| Phase and connecting | 3phases 4wires /3phases 3wires | |||||

| Dimension (L×W×H) (mm) | 5800×1600×2900 | 6400×1600×2900 | ||||

| Weight(kg) | 18000 | 22000 | ||||

ØLarge cylinder, ensure stable and constant power output

Large cylinder, long stroke, low speed and big power reserves, ensure stable and constant power output.

ØLow speed ensure service life

Low &medium speed reduces components wear, extends service life, reduces components inventory and improve economic benefit.

ØNaturally aspirated

Naturally aspirated, low gas intake pressure requirement (gas pressure ≥2kPa), strong adaptability to gas pressure fluctuation.

ØNon-turbocharged naturally aspirated, double tube gas intake system with high tar tolerance;

Ø Intake valve kit is removable for easy maintenance;

Ø External or internal mixing system can be selected according to hydrogen content;

Ø Adapt to low calorific value gas with high hydrogen content;

Ø High degree of automation, high safety and low operating costs.

Why Zichai Gas Generator Set?

1. Development and manufacturing internal combustion engine since 1970

2. Factory area over 330000m2 & over 2200 employees

3. Highly versatile power generator with ability to handle more than 20 different gases

4. More than 200 employees dedicated to developing and improving power generator for various gas.

5. More than 1000 systems installed in over 20 countries using a variety of gases.

6. More than 50 people in the Customer Service Department making the Organization very Customer Responsive.

Project References

FAQ

1.Are you a trading company or manufacture?

Manufacture with factory.

2.What kinds of gas generator set do you produce?

It covers for all kinds of gas produced in agriculture and industry, including biomass gas, biogas, natural gas, coal mine gas, coke oven gas, semi-coke gas and syngas, as well as related gas produce equipment.

3.What is your delivery time?

Normally within 60days, it depends on the configuration and quantity, please confirm with us before order.

4.What is your payment terms?

T/T or L/C.

5.How do you pack products?

Standard export packaging. Equipment packing with plastic bag, and with new solid wooden box, suitable for long-distance sea transportation, moisture-proof, earthquake, rust-proof and anti-brutal handling.

6.What is your available port of shipment?

Normally Qingdao port, other ports available according to customers' requirement.